How can you avoid foot pain when wearing safety shoes?

Foot pain can be a real problem for some people who wear safety shoes. This discomfort can be the result of a number of factors, from incorrect sizing to material choices. In this article, we'll explore the most common causes of this pain and offer practical solutions to prevent it.

Sore feet in safety shoes: the most common problem

Wrong sizeWhen it comes to foot pain when wearing safety shoes, the first problem is often the wrong size. Buying the wrong size can cause a variety of problems, from painful blisters to chronic heel and toe pain. Shoes that are too small will squeeze your feet, while shoes that are too big can cause chafing and skin injury. Choosing the right shoe size is essential to ensure maximum comfort all day long. It is important to measure your feet correctly and choose a size that allows enough range of motion while providing good support.

Toe cap problemsThe toe cap is often the most important point in safety shoes. Some workers may experience toe pain, friction, and unwanted impact during a collision. It is important to choose shoes with a sturdy and comfortable toe cap to ensure maximum protection and foot well-being while you work. A poorly designed toe cap made of low-quality materials can cause serious injuries and jeopardize the safety of the wearer.

But only oneThe insole plays a crucial role in the comfort of safety shoes. An improper insole can result in poor weight distribution, leading to pain in the feet, knees and even back. All these problems are called musculoskeletal disorders. In France, according to Santé Publique France, MSD (musculoskeletal disorders) is the most common occupational disease. For your safety shoes, an ergonomic insole and outsole that adapts to the usage and shape of the foot will greatly improve the overall comfort.

Some tips to avoid foot pain when wearing safety shoes

The right size of safety shoesIt is important to remember that your foot size can fluctuate depending on your posture, weight, and other factors. Sometimes it is necessary to get accurate foot measurements before buying new shoes, as not all manufacturers use the same measurement method.

If you don’t have a foot measuring device, here are some parade tips to accurately measure your feet.

First of all, it is best to take this measurement at the end of the day. Why? Because during the day, feet tend to swell, making them larger in the evening than in the morning. Put on your regular pair of socks. Stick a piece of white paper on the floor and make sure the paper doesn't move using masking tape. Then, stand on the paper with your foot on it. Using a pen, trace the outline of your foot and mark where the big toe is and the back of the heel. Repeat this process with your other foot.

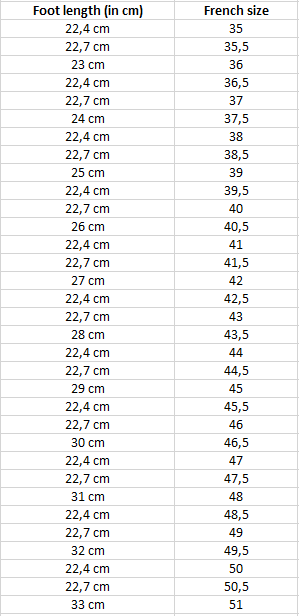

Use a ruler to measure the length between the two marks you made. Finally, enter your measurements in this chart to find your shoe size:

Are your feet different sizes? Don't worry, use the largest size. Choose a shoe size that gives you enough room to move around while providing the best support.

Please note that shoe size is not determined solely by foot length. Feet can vary in shape from narrow to medium or wide.

This explains why we may not get the same feel and comfort when switching from one shoe to the other.

In short, the size you choose will depend on the volume and length.

Proper fastening of your safety shoesProperly tying your safety shoes is important for several reasons:

- Stability and Support: Proper lacing keeps your feet secure in your shoes, reducing the risk of slipping and twisting. Lacing too tight can restrict blood flow, causing numbness, pain, and even injuries like corns or calluses. Lacing too tight can also cause problems with the joints and muscles of your feet, leading to increased discomfort and fatigue during your workday. Therefore, it is important to strike a balance when lacing your shoes, providing a snug fit without compromising comfort and blood flow.

- Injury Prevention: Properly laced shoes can help prevent blisters, chafing, and injuries caused by improper footwear.

- Comfort: Proper lacing provides a comfortable fit, essential for those who work long hours or move around in demanding work environments.

- Safety: In the workplace, safety footwear must fit properly to ensure optimum protection against potential work hazards, such as sharp objects, chemicals, or falling heavy objects.

1. Position your heel correctly on the bottom of the shoe so that it fits snugly against the heel area.

2. Stretch the shoelace from eyelet to eyelet, starting from the tip of the shoe.

3. Tie the rope neatly using all the eyelets and pull the rope tight.

4. Check that your shoes are tied correctly by checking that the laces are tight from top to bottom.

5. Adjust the laces every two hours as the laces loosen and the foot volume changes throughout the day.

The ergonomics of the insole have a direct impact on the comfort of the shoe. Invest in an insole designed to absorb shock and provide extra arch support to reduce fatigue and absorb shock.

At Parade, we have developed a number of technologies inspired by the natural shape of the foot – the arch, the entire architecture that encompasses the bones, joints, tendons and muscles of the foot. These technologies are found in the soles of your safety shoes. Let us introduce you to them:

> VPS (Arch Support System): The ergonomic shape of the shoe maintains the natural arch of the foot following the arch of the foot. This insole provides unparalleled comfort, especially in the case of small steps or long periods of walking and standing.

> DRS (Delete Resonance System): Our DRS technology is located in the heel and acts as a shock absorber. DRS is a hemispherical indented channel under the heel. As the heel makes contact with the terrain, this channel drops inward and moves along the heel to adapt to the terrain, ahead of foot roll and forward movement. You'll find DRS 2 on our Racing sport sole.

> Parade Air System: The PARADE AIR SYSTEM is an air bubble encased in the outsole of the shoe. This air cushion technology increases flexibility while walking.

> FLEX SYSTEM: FLEX SYSTEM technology is ideal for construction and uneven surfaces. The special design of the sole with grooves reduces pressure on the sole, providing flexibility and comfort when walking. The shoe moves with the foot and has horizontal grooves and notches under the metatarsal bones, where the foot naturally flexes and naturally dislodges soil as the foot moves forward. This technology is available on all our models with NEBRASKA and NEVADA soles.

> Be Flex 2.0: BE FLEX 2.0 technology is designed for tasks that require flexibility and walking comfort, such as transport. The raised side of the sole sits lower in the forefoot to facilitate easy flexion. The forefoot features a special design with three transverse grooves for maximum movement and flexibility in the forefoot.

Worn out soles increase the risk of slipping and eventually accidents. It is necessary to regularly check the condition of the studs in the shoes to assess the level of wear. Good quality safety shoes can help:

- Keep you safe: Safety shoes in good condition provide maximum traction and reduce the risk of slips, falls, and accidents on slippery or uneven surfaces.

- Stay Healthy: Poor posture, joint pain, and muscle injuries can contribute to poor posture. Changing your shoes regularly can reduce your risk of musculoskeletal disorders (MSDs).

- Improves Work Efficiency: Safety shoes in good condition improve worker comfort and well-being, which can have a positive impact on work performance and concentration.

- Follow safety standards: In many workplaces, current laws or safety standards require regular replacement of personal protective equipment, including safety footwear. Following these guidelines helps ensure compliance with workplace safety regulations.

Replacing your safety footwear regularly helps maintain a safe working environment, prevent work-related injuries, and ensures compliance with safety standards. It's an investment in your employees' safety and well-being, as well as your company's overall performance. For this reason, Parade recommends replacing your equipment every 6 months to 1 year, depending on their wear and tear.

Safety socks are specially designed to be worn with protective footwear, reducing discomfort. They provide extra cushioning and moisture absorption, keeping your feet more comfortable.

Let's talk about the two Parade socks:

Made primarily from cotton, Madrid socks are soft and comfortable, ideal for sensitive skin. They feature a reinforced heel and toe to prevent tearing. Available in a pack of 3 pairs, they are essential for everyday use or professional use with safety shoes.

The Miami New socks feature a breathable design with an open mesh upper and a ventilation strip under the toe. They're quick-drying, durable and comfortable with polyamide toe and heel reinforcements and a high collar to prevent abrasion. Sold in a pack of two, they're versatile and easily pair with a variety of footwear types, from safety sneakers to everyday shoes.

Madrid and Miami New socks come together to offer a wide range of options to meet different needs for comfort, durability and breathability, whether for work or leisure.