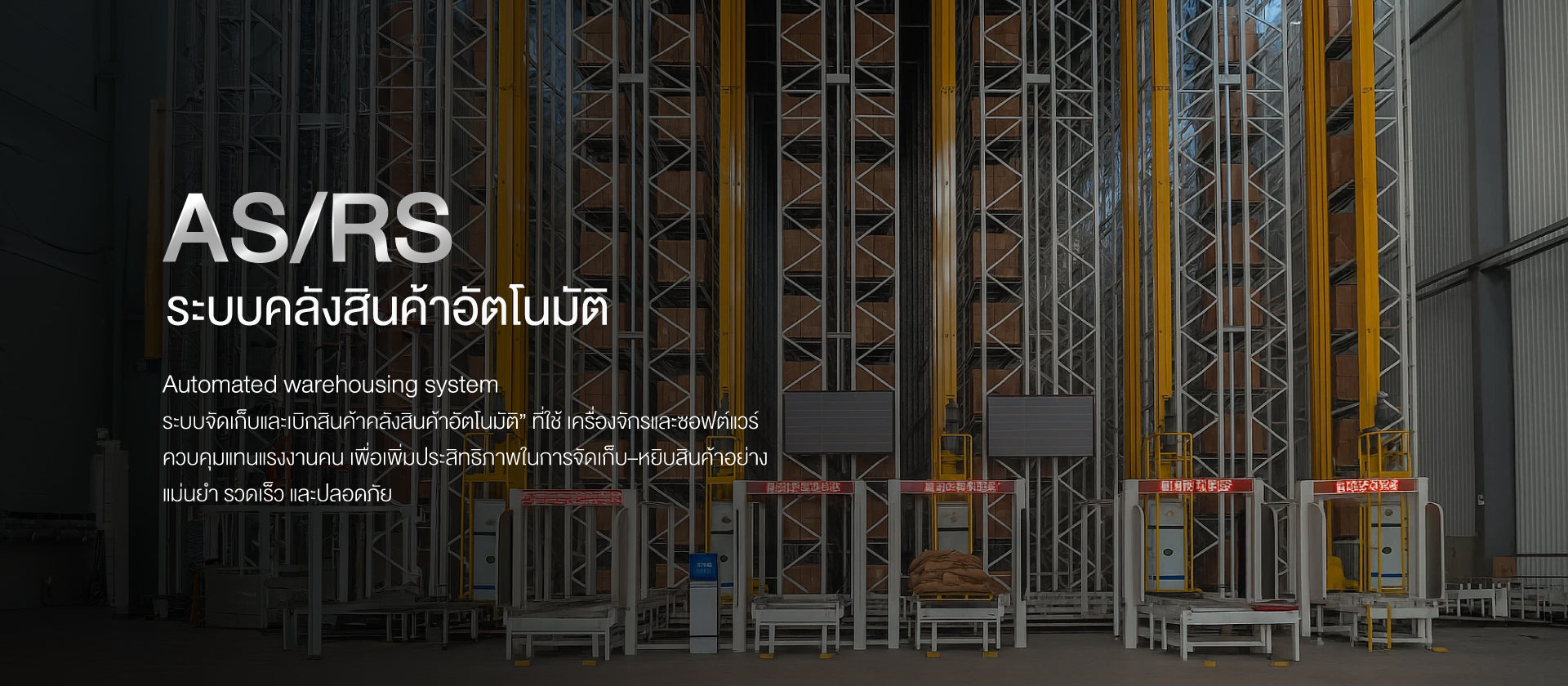

AS/RS Warehouse System

Automated Warehouse

AS/RS automates storage and retrieval with computer-controlled cranes or shuttles, reducing labor, improving accuracy, maximizing vertical space, and enabling real-time inventory visibility.

An automated storage and retrieval system uses cranes or shuttles to cut labor, boost accuracy, optimize space, and control inventory in real time for high speed large warehouses.

Using technologies like AS/RS, material handling robots, and WMS to automate storage and retrieval reduces manual workload and errors, speeds up operations, maximizes vertical space, and enables real time inventory control, helping cut long term operating costs.

Automation also improves warehouse safety by reducing accidents from manual handling, and it can operate 24/7 without breaks. This helps businesses handle more orders and gain a competitive edge in the Industry 4.0 era.

Using AS/RS, handling robots, and WMS to automate storage and retrieval reduces errors, speeds up operations, maximizes vertical space, enables real time inventory control, and lowers long term operating costs.

Using AS/RS, handling robots, and WMS to automate storage and retrieval reduces errors, speeds up work, maximizes vertical space, enables real time stock control, and cuts long term costs.

Automation also enhances warehouse safety by reducing accidents from manual handling, and it can run continuously 24/7 without breaks. This allows businesses to handle more orders and gain a competitive edge in the Industry 4.0 era.

ขั้นตอนการทำงาน Our Process

คุยโจทย์กับลูกค้า Requirement Briefing

รับฟังความต้องการ พื้นที่ใช้งาน ประเภทสินค้า และงบประมาณ เพื่อวางแนวทางเบื้องต้นของระบบคลังสินค้าอัตโนมัติ ให้เหมาะกับธุรกิจและสามารถต่อยอดได้ในอนาคต We gather your requirements, space details, product types, and budget to define the right automated warehouse direction that fits your business and can scale in the future.

สำรวจพื้นที่จริง On-site Survey

ลงพื้นที่วัดขนาด ดูโครงสร้างอาคาร ทางเดินรถโฟล์คลิฟต์ และข้อจำกัดหน้างาน เพื่อออกแบบเลย์เอาต์และระบบจัดเก็บได้แม่นยำ We measure dimensions, check building structure, forklift routes, and site constraints to design an accurate layout and storage system.

ออกแบบและเสนอราคา Design & Quotation

วางผังชั้นวางและระบบอัตโนมัติ คำนวณความจุ ประเมินการไหลของสินค้า พร้อมเสนอแบบและใบเสนอราคาอย่างชัดเจน We plan racking and automation, calculate capacity, evaluate product flow, and provide clear drawings and a quotation.

ผลิตและติดตั้ง Fabrication & Installation

ผลิตโครงสร้างและอุปกรณ์ตามแบบ ติดตั้งโดยทีมงานมืออาชีพ ตามมาตรฐานความปลอดภัยและกำหนดเวลาที่ตกลงกัน We fabricate the structure and equipment to spec, then install with a professional team under safety standards and the agreed timeline.

ทดสอบระบบและส่งมอบ Testing & Handover

ทดสอบจริง ปรับจูนให้ลื่นไหล อบรมทีมปฏิบัติการ พร้อมส่งเอกสารครบถ้วน We run real tests, fine-tune for smooth operation, train your team, and deliver complete documentation.

สนใจระบบคลังสินค้าอัตโนมัติ Interested in warehouse automation?

ปรึกษาเซลล์ Contact Sales

Top Warehouse Automation

An automated warehouse system uses robots or shuttles to automate storage and retrieval, improving speed and accuracy, saving space, and reducing manual errors.

ระบบคลังอัตโนมัติ AS/RS

Automated Storage & Retrieval System (AS/RS)

บริการของเรา Our Services

Step into the era of

Automated Warehouse

When e-commerce and supply chains demand greater speed and accuracy, traditional warehouses are no longer enough. Our AS/RS systems and automation solutions help design warehouses that can handle high order volumes, reduce costs, and manage inventory in real time.

Scale your warehouse for high e-commerce order volumes, cut costs, and control inventory in real time.

We deliver end-to-end automated storage systems, from site survey and layout planning to installation and team training. Built to scale with your future inventory and production growth.

Automated Warehouse Install

All Over Thailand

We deliver end-to-end AS/RS solutions from design to installation and testing, improving storage efficiency, cutting labor costs, and enhancing warehouse safety.

End-to-end AS/RS solutions: plan, design, install, and test to boost efficiency, cut labor costs, and improve warehouse safety.

FAQ

What is a 3D Sorting system?

An automated sorting system that uses robots to move parcels in 3D (horizontal and vertical) for fast, accurate routing, ideal for high-volume e-commerce warehouses and distribution centers.

How is it different from a conveyor-based sorting system?

3D Sorting uses autonomous robots instead of conveyors, so it’s more flexible, more space-efficient, faster to deploy, and easier to scale without downtime.

What is the sorting speed?

The system can sort from hundreds to thousands of items per hour per unit, and it can be easily scaled by adding more robots and destination chutes.

How much space is required?

The required installation space is highly flexible, ranging from a few hundred to several thousand square meters. Since the system is modular, it can be laid out to fit your available space.

Is it difficult to operate? / How long does training take?

The system is designed for ease of use with a graphical control interface, and basic operation can be learned in just a few minutes.

Do we need the same number of staff?

It can reduce sorting labor by 50–80% and cut human errors by over 99%.

What is the approximate payback period (ROI)?

In most cases, the payback period is 1–2 years, depending on your throughput and the level of automation installed.

What do we need to prepare for a 3D Sorting system?

- Work goals & key metrics

- Target sorting throughput (pieces/hour)

- Operating hours/shifts, peak vs off-peak volumes

- Number of destinations/chutes needed (current + expansion)

- Sorting rules (province/ZIP/sales channel)

- SLA: accuracy, cycle time, and contingency plan for disruptions

- Items & packaging

- Parcel size/weight range (min–max)

- Packaging material and shape (flat/curved surfaces)

- Barcode/QR standards (type, placement, re-scan rate/quality)

- Tote/carton labeling requirements

- Exceptions: fragile, liquid, magnetic, lithium, etc.

- Facility / site space

- Site layout flow (inbound → sorting → outbound)

- Aisles and emergency exits

- Floor condition: flat, strong, and load-bearing per spec

- Sufficient ceiling height and lighting

- Robot charging/parking zone, buffer zone, and manual exception station

- Power & network

- Main power + backup (UPS/generator)

- Breakers, power rails/cable trays sized to load

- LAN/Wi-Fi for devices and robots, separate VLAN, AP coverage

- Cybersecurity policy (access control, CCTV, log retention)

- Software systems & integration

- Existing WMS/ERP/OMS

- Integration method (API/CSV/Message Queue)

- Data mapping: order keys, destination codes, rule tables

- Control dashboard mapping, alerts, KPI reports (Throughput/Accuracy/Downtime)

- Safety & compliance

- Safety measures: fencing, E-stops, warning signs, restricted zones

- Local regulations/requirements (fire safety, floor load, emergency routes, insurance)

- People & processes

- Operations team structure per shift

- Roles: Supervisor / Operator / Technician

- SOP for inbound–sort–outbound, exception handling (e.g., unreadable barcode)

- Training plan (basic 5–15 minutes + quarterly refresh)

- Maintenance & spare parts

- Preventive/Corrective maintenance plan (PM/CM)

- Critical spares (scanner, wheels, batteries, belts, etc.) and toolkits

- Support SLA, incident reporting channel, response/resolution times

- Testing & handover

- FAT/SAT/UAT criteria: normal/peak/emergency scenarios

- Barcode read rate, accuracy targets

- Pilot & ramp-up plan, acceptance criteria

- Documentation checklist (manuals, electrical/network diagrams, etc.)

- Budget & timeline

- Budget breakdown (hardware/software/services) + monthly OPEX

- Phased rollout roadmap

- Future expansion plan (more chutes/robots)

- Estimated ROI/payback assumptions